- Have any questions?

- +263 (242) 777 797

- salesharare@urh.co.zw

BRAMMER / LINK

February 14, 2019

GRIPFACE (RUBBER & PVC)

February 14, 2019CONVEYOR BELT

APPLICATION

Mainly used in mining, quarrying, heavy industry, belts transport loose or packed material over long or short distances on various gradients and are one of the cheapest forms of transport on a continual basis.

TENSILE STRENGTH

Measured in kilograms of force applied per centimeter of conveyor belt width. Standard tensile strengths are :

KG/CM IMPERIAL EQUIVALENT

125 T70

200 T112

250 T140

Tensile strengths increase with heavy-duty applications as follows:

315, 400, 500, 630, 800, 1000, 1250, 1500.

Above 1500 kg/cm use steel cord conveyor belts, see later.

A conveyor belt tensile strength is determined by the number of plies and the strength of each ply,depending on material used, e.g. nylon or polyester. This explains the CLASS of conveyor belt sometimes referred to as a measure of strength.

FOR EXAMPLE

T70 3 PLY = EP125 3 PLY = 125 x 3 = CLASS 375

T112 3 PLY = EP200 3 PLY = 200 x 3 = CLASS 600

T140 4 PLY = EP250 4 PLY = 250 x 4 = CLASS 1000

CARCASS PLIES

These range from 2 to 6 ply and are either a polyester/nylon mix (EP) or nylon only (NN).

EP conveyor belts are preferred due to :

a. Less stretch than nylon belts;

b.Troughing capability thanks to flexibility.

Sealed edge conveyor belts protect the plies from moisture and separation.

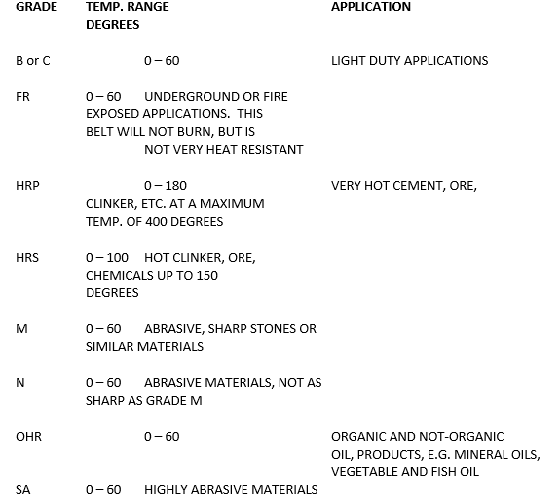

GRADE OF COVERS

Different conveyor belt qualities or grades, suit particular applications.

COVERS – TOP AND BOTTOM

a) TOP COVER

This protects the carcass plies from material damage. Abrasive, sharp stones falling onto a belt will need a 5mm or greater top cover, while belts carrying softer materials need only have a 3mm top cover. Minimum 2mm, maximum 10mm.

b) BOTTOM COVER

This protects the carcass plies from the conveyor bed rollers and guides, and prevents wet material build up on the underside of a belt. Similar to the top cover, abrasive materials will require a bottom cover of up to 5mm; while the normal thickness is 1.6mm.

STEEL CORD CONVEYOR BELTS

These conveyor belts have many high tensile, steel cords running lengthwise through the belt instead of carcass plies. This offers:

a) Extreme high tensile strength, up to 5000 kg/cm;

b) Minimal belt stretch for long conveyors;

c) Good tough ability and impact resistance.

Steel cord belts are most suited to extra-long belt systems, e.g. 1km drives, carrying heavy materials on a troughed conveyor. Hwange Colliery, Zisco Steel and some large mines with inclining main shafts would require these conveyor belts.